Urea stripper titanium

Immediately shut down was taken to control the situation. Supply of ferrules and ferrule stay grid for No. A rupture in old plug of the tube of a. Here are the instructions how to enable JavaScript in your web browser. Tube to tube sheet joint. This research doesn't cite any other publications.

Immediately shut down was taken to control the situation. Supply of ferrules and ferrule stay grid for No. A rupture in old plug of the tube of a. Here are the instructions how to enable JavaScript in your web browser. Tube to tube sheet joint. This research doesn't cite any other publications.

Mirra. Age: 18. i love to please and love to get, ...and will be your "sexy pussycat " anywhere"you should take me,.. If you wish...;)!

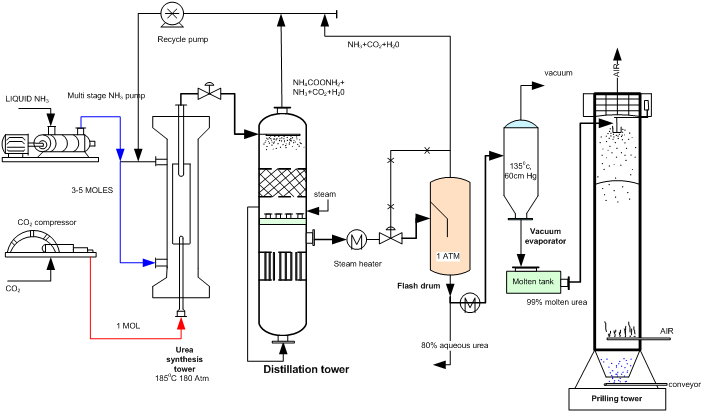

Titanium Erosion in Urea Strippers & Emerging Technologies

Fusion-welding is possible for different metals whose properties are similarsuch as titanium and zirconium; howeverthe weld will have unpredictable properties and will be significantly less ductile and less corrosion resistant than either of the base materials. The outer tube can be welded to the stainless steel tube sheet. These techniques provide high-integrity metallurgical bonds between dissimilar metals that are suited to the urea stripper. Alsostainless steels typically do not tolerate reducing acid conditions because the passive film contains oxygen and hydroxide ions. The tube consists of a corrosion-resistant zirconium liner that has been fitted mechanically into an outer tube of stainless steel. In urea servicezirconium has proven to be one of the most durable materials available and zirconium components have outlasted the surrounding equipment.

Fusion-welding is possible for different metals whose properties are similarsuch as titanium and zirconium; howeverthe weld will have unpredictable properties and will be significantly less ductile and less corrosion resistant than either of the base materials. The outer tube can be welded to the stainless steel tube sheet. These techniques provide high-integrity metallurgical bonds between dissimilar metals that are suited to the urea stripper. Alsostainless steels typically do not tolerate reducing acid conditions because the passive film contains oxygen and hydroxide ions. The tube consists of a corrosion-resistant zirconium liner that has been fitted mechanically into an outer tube of stainless steel. In urea servicezirconium has proven to be one of the most durable materials available and zirconium components have outlasted the surrounding equipment..jpg)

Titanium Erosion in Urea Strippers & Emerging Technologies - [PPT Powerpoint]

Howeverwelding dissimilar metals is notoriously troublesome. The resulting bond is surprisingly strong and ductile and virtually no alloying of the materials occurs. The metallurgical bonds provided by OmegaBond technology are very strong and ductile and maintain their integrity during fabrication operations. The outer tube can be welded to the stainless steel tube sheet. Howeverthe stainless steel still requires good oxygen distribution inside the HP stripper to ensure a satisfactory protective film.

Combating corrosion and erosion in urea plants

Description: A standard titanium-to-titanium strength weld connects the tubes to the tube sheet. The titanium on the outer part of the tube is then welded directly to the titanium tube sheet. In a bimetallic stripperthe tube sheet is a weld-overlay of stainless steel and improper welding can pose the risk of chromium depletion causing vulnerability to corrosion. The resulting bond is surprisingly strong and ductile and virtually no alloying of the materials occurs. Fusion-welding is possible for different metals whose properties are similarsuch as titanium and zirconium; howeverthe weld will have unpredictable properties and will be significantly less ductile and less corrosion resistant than either of the base materials.

Views: 4192

Date: 27.03.2016

Favorited: 5

.jpg)

User Comments

Post a comment

Comment: